Views: 0 Author: Site Editor Publish Time: 2025-08-06 Origin: Site

Have you ever wondered why certain steel structures withstand the test of time while others rust away? Galvanized steel might be the answer. This durable material, coated with zinc, is crucial in industries like construction and automotive. In this article, you'll learn about galvanized steel's composition, benefits, applications, and how it compares to other materials. Discover why it's a top choice for long-lasting projects.

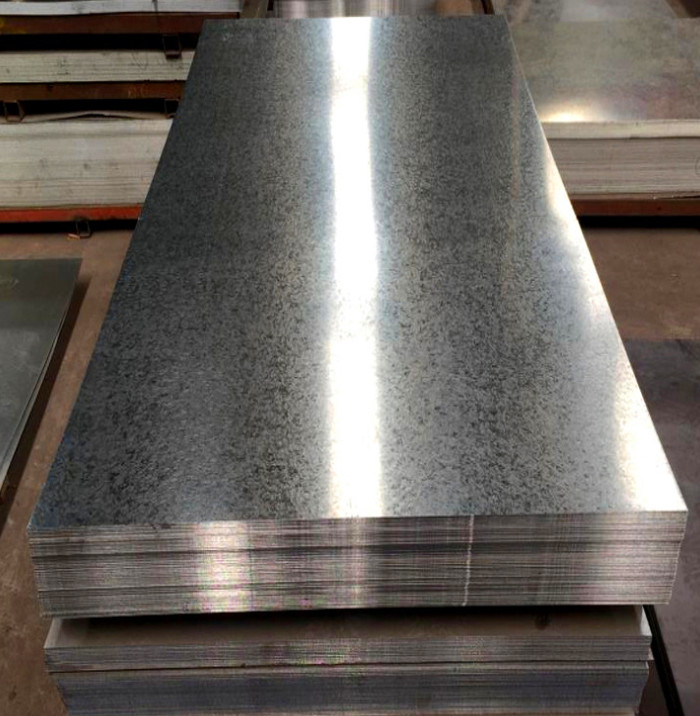

Galvanized steel is steel coated with a thin layer of zinc to protect it from rust and corrosion. The zinc acts as a shield, preventing moisture and oxygen from reaching the steel underneath. This protective layer enhances the steel’s durability and gives it a distinctive silvery-gray finish, often spotted with a unique pattern called a spangle. This pattern looks like tiny crystals spread across the surface, a sign of quality galvanization.

The base metal is usually carbon steel or iron. When zinc covers it, the steel gains resistance to environmental damage, making it ideal for outdoor use. The zinc coating doesn’t just sit on the surface—it bonds tightly, creating a strong barrier against wear and tear.

Galvanizing involves applying zinc to steel through several key steps:

Cleaning: The steel is first cleaned to remove grease, dirt, and rust. This prepares the surface for proper zinc adhesion.

Pickling: Steel is dipped in an acid bath to eliminate scale and impurities.

Fluxing: The steel is treated with a flux solution, usually zinc ammonium chloride, to prevent oxidation before zinc coating.

Coating: The steel is immersed in molten zinc, usually heated around 450°C (842°F). This hot-dip galvanizing forms a metallurgical bond between zinc and steel.

Cooling: The coated steel is cooled, often in a quench bath, which may contain passivation agents to prevent white rust.

This process ensures the zinc layer covers every surface, including corners and recesses, for complete protection.

Several methods exist to apply zinc coating, each suited for different needs:

Hot-Dip Galvanizing: The most common method. Steel is dipped in molten zinc, creating a thick, durable coating. It’s perfect for structural steel, outdoor equipment, and industrial parts.

Electrogalvanizing: Zinc is deposited onto steel using an electric current in an electrolyte solution. This creates a thinner, smoother coating ideal for automotive panels and electronic components.

Pre-Galvanizing: Performed at the steel mill, steel sheets or strips are coated before fabrication. It’s efficient for mass production but offers less corrosion resistance on cut edges.

Galvanizing Annealing: Steel is heated in a controlled atmosphere to allow zinc diffusion, producing a thin, uniform coating. Often used for products needing smooth finishes for painting.

Each method balances cost, durability, and finish quality. Hot-dip galvanizing offers the best corrosion resistance but can alter the steel’s dimensions slightly. Electrogalvanizing provides a precise finish but with thinner protection.

Galvanized steel offers several key advantages that make it a top choice across industries. Its protective zinc coating not only shields steel from damage but also delivers long-lasting performance. Here’s a closer look at the main benefits:

One of galvanized steel’s standout features is its excellent resistance to corrosion. The zinc layer acts as a barrier, preventing moisture and oxygen from reaching the steel underneath. Even if the coating gets scratched, zinc sacrifices itself by corroding first, protecting the base metal from rust. This sacrificial protection is crucial in harsh environments like coastal areas, industrial zones, or places exposed to rain and humidity.

Thanks to its corrosion resistance, galvanized steel lasts much longer than untreated steel. It can endure 50 years or more in typical conditions without significant wear. In more aggressive settings, it still provides decades of reliable service. This durability reduces the need for frequent repairs or replacements, making it ideal for infrastructure, automotive parts, and outdoor construction.

Galvanized steel offers great value over its lifespan. While the initial cost might be higher than plain steel, the long-term savings are significant. It requires little maintenance—no regular painting or treatment—and avoids costly corrosion damage. This low upkeep means fewer interruptions and lower lifecycle costs, especially for projects where durability is critical.

Galvanized steel supports sustainability goals. It uses zinc, a naturally abundant, non-toxic material, which is fully recyclable. The long service life means less frequent replacement, reducing waste and resource use. Additionally, the galvanizing process produces minimal waste and emissions compared to other protective coatings. Many manufacturers provide Environmental Product Declarations (EPDs), confirming the eco-friendly nature of galvanized steel products.

Galvanized steel finds its way into many industries thanks to its strength, corrosion resistance, and long-lasting nature. Let’s explore some key areas where it shines:

Galvanized steel is a backbone in construction projects. It’s used for bridges, roofing, fencing, and structural supports. Its zinc coating prevents rust, making it perfect for outdoor elements exposed to weather. Think of guardrails on highways or light poles in parks—they often use galvanized steel to stay strong over decades. Its durability reduces maintenance costs and keeps structures safe and reliable.

Around 80% of car bodies include galvanized steel. Why? Because it protects vehicles from rust caused by rain, snow, and road salt. This means cars last longer and need less repair. The zinc layer also helps prevent scratches from turning into rust spots, maintaining the car’s appearance and safety. From chassis to body panels, galvanized steel is a trusted material in vehicle manufacturing.

Galvanized steel is popular around homes too. It’s found in gutters, fences, gates, and even structural supports like lintels and stumps. Homeowners appreciate its low maintenance and resistance to weather damage. Plus, it can be painted easily, allowing it to match any home style. Its strength and longevity make it a cost-effective choice for many residential projects.

In factories and plants, galvanized steel is everywhere. It’s used for storage tanks, piping, and structural beams. Chemical plants and energy facilities rely on it because it resists corrosion from chemicals and moisture. The mining industry also benefits from galvanized steel in walkways, conveyors, and protective enclosures, where harsh conditions demand tough materials. Its ability to withstand wear and tear helps keep industrial operations running smoothly.

Galvanized steel and stainless steel both resist corrosion, but they do so differently. Galvanized steel relies on a zinc coating that protects the steel underneath by acting as a barrier and a sacrificial layer. If scratched, zinc corrodes first, sparing the steel. Stainless steel, on the other hand, contains chromium, which forms a thin, invisible oxide film on the surface. This film prevents rust without needing any additional coating.

Cost is a major difference. Galvanized steel usually costs less upfront than stainless steel. However, stainless steel offers longer-lasting corrosion resistance without maintenance or recoating. It’s often chosen for applications requiring high hygiene standards, like food processing or medical equipment, because it resists staining and is easy to clean.

Physically, stainless steel tends to be stronger and more resistant to heat and chemicals, making it suitable for harsh environments. Galvanized steel works well outdoors or in less demanding settings, especially where budget constraints exist.

Aluminum and galvanized steel both offer corrosion resistance but differ in weight and strength. Aluminum is naturally corrosion-resistant because it forms a protective oxide layer. It is much lighter than galvanized steel, making it ideal for applications where weight savings matter, such as aircraft or automotive parts.

Galvanized steel, being heavier, provides higher tensile strength and durability. It’s often preferred for structural uses, like bridges or fencing, where strength is critical. Aluminum may dent or scratch more easily, while galvanized steel’s zinc coating helps protect against surface damage.

Cost-wise, aluminum usually costs more per pound but can lower transportation or installation expenses due to its lightness. Galvanized steel is more affordable and widely available, making it popular in construction and industrial uses.

| Material | Advantages | Disadvantages |

|---|---|---|

| Galvanized Steel | Cost-effective, strong, good corrosion protection | Zinc coating can wear off, heavier than aluminum |

| Stainless Steel | Excellent corrosion and heat resistance, low maintenance | Higher initial cost, harder to machine |

| Aluminum | Lightweight, naturally corrosion-resistant, easy to work with | Lower strength, higher cost, can scratch easily |

Choosing between these materials depends on your project’s needs. If budget and strength matter most, galvanized steel is a solid choice. For high corrosion resistance and low upkeep, stainless steel excels. When weight reduction is key, aluminum stands out.

Understanding these differences helps you pick the best material for durability, cost, and performance.

Choosing quality galvanized steel is crucial for ensuring your project lasts and performs well. Here are some key points to consider when selecting the right galvanized steel.

Zinc Coating Thickness: Thicker zinc layers provide better corrosion protection. Look for coatings measured in grams per square meter (g/m²) or mils. For outdoor or harsh environments, thicker coatings like those from hot-dip galvanizing are preferred.

Surface Appearance: Quality galvanized steel has a smooth, bright, and uniform finish. The classic spangle pattern—tiny crystal-like spots—is a sign of proper galvanization. Avoid steel with dull, patchy, or rusty spots.

Steel Grade: The base steel's quality matters. Higher-grade steels offer better strength and durability. Confirm the steel grade suits your project requirements, especially for structural or load-bearing uses.

Application Environment: Consider where the steel will be used. Coastal or industrial areas require more corrosion-resistant coatings. Indoor or less harsh environments might allow thinner coatings or pre-galvanized steel.

ASTM Standards: The American Society for Testing and Materials sets benchmarks like ASTM A123 for hot-dip galvanizing. Compliance ensures consistent coating quality and thickness.

JIS and AS/NZS: Japanese Industrial Standards (JIS) and Australian/New Zealand Standards (AS/NZS) also regulate galvanized steel quality. Look for products meeting these if sourcing internationally.

Environmental Product Declarations (EPD): Some manufacturers provide EPDs, showing environmental impact and sustainability credentials. This is useful for green building projects.

Manufacturer Reputation: Choose suppliers known for high-quality galvanizing processes. Check for certifications, production capacity, and years of experience.

Inspect Samples: Always request samples before bulk purchase. Check coating uniformity, adhesion, and surface finish.

Check Labels and Traceability: Quality products often feature labels or QR codes showing origin and compliance certificates. This adds transparency.

Ask About Coating Testing: Inquire if the supplier performs adhesion tests, thickness measurements, and corrosion resistance evaluations.

Understand Warranty and Support: Reliable manufacturers provide warranties covering coating performance and offer technical support.

Consider Total Cost: Don’t just look at upfront price. Factor in maintenance, lifespan, and replacement costs. Higher-quality galvanized steel often saves money long-term.

Galvanized steel is designed to resist rust effectively. The zinc coating acts as a protective shield, stopping moisture and oxygen from reaching the steel underneath. Even if the coating gets scratched or damaged, zinc provides sacrificial protection—it corrodes first to protect the steel beneath. However, if the zinc layer wears away completely or is compromised over a large area, the steel can start to rust. This means that while galvanized steel is highly resistant to rust, it is not entirely rust-proof if the protective layer is lost. Proper maintenance and avoiding harsh environments can help extend its rust resistance.

Yes, galvanized steel is generally safe for food contact in many applications. Zinc is a non-toxic metal, and the coating is widely used in food storage, processing equipment, and water pipes. However, there are some considerations:

Direct Food Contact: For prolonged direct contact with acidic or salty foods, galvanized steel may not be ideal because acids can react with zinc, potentially causing corrosion or zinc leaching.

Regulations: Food safety regulations vary by country. Products intended for food contact often meet specific standards ensuring safety and hygiene.

Surface Condition: Galvanized steel should have an intact, clean coating to prevent contamination.

In many cases, galvanized steel is used safely in food-related environments, but for direct contact with highly acidic foods, stainless steel may be preferred.

You can identify galvanized steel through several simple methods:

Appearance: It has a distinctive silvery-gray finish with a spangle pattern—tiny, crystal-like spots or mottled textures on the surface. This pattern results from the zinc crystallizing during cooling.

Magnet Test: Since the base metal is steel, a magnet will stick firmly to galvanized steel.

Scratch Test: Carefully scratching a small, inconspicuous area can reveal a shiny zinc layer over steel. If the material underneath is steel-colored, it confirms galvanization.

Weight and Feel: Galvanized steel feels similar to regular steel but may be slightly heavier due to the zinc coating.

Labels or Marks: Some products come with manufacturer labels or stamps indicating galvanization.

Using these methods together provides a reliable way to confirm if steel is galvanized.

Galvanized steel is durable, corrosion-resistant, and cost-effective, making it ideal for construction and manufacturing. Its zinc coating protects against rust, ensuring longevity. As industries prioritize sustainability, galvanized steel's recyclability and minimal maintenance will drive future demand. Zhongrun Steel (Foshan) Co., Ltd. offers high-quality products with superior zinc coatings, enhancing performance and value. Their expertise ensures reliable solutions for diverse applications, reinforcing the material's importance in modern projects. Galvanized steel remains a vital choice for strength and resilience.

A: Galvanized steel is steel coated with zinc to protect it from rust and corrosion.

A: It is made by cleaning steel, dipping it in molten zinc, and cooling it to form a protective layer.

A: It offers corrosion resistance, durability, cost-effectiveness, and environmental sustainability.

A: It is used in construction, automotive, residential, and industrial applications.

A: Look for a silvery-gray finish with a spangle pattern, and use a magnet test.