How to Choose the Right Carbon Steel Coil: Differences Between Hot-Rolled and Cold-Rolled Steel and Their ApplicationsWhen selecting the right carbon steel coil for your project, understanding the distinctions between hot-rolled and cold-rolled processes is crucial. The choice between these two type

IntroductionGalvanized pipe fittings and pipe have become indispensable in modern construction, manufacturing, and infrastructure projects. By applying a zinc layer to steel through the hot-dipped galvanize steel process, these pipes achieve superior corrosion resistance and durability. As a result,

Galvanized steel pipes are widely used across industries and construction projects because of their durability, corrosion resistance, and cost-effectiveness. When choosing materials for plumbing, structural frameworks, or industrial applications, selecting the best galvanized steel pipe ensures both

Choosing the Best Galvanized Pipe: Complete Buyer’s GuideWhen it comes to construction, water systems, or industrial frameworks, selecting the right pipe is essential. Among the most trusted materials, galvanized pipe stands out due to its strength, cost-effectiveness, and long service life. This gu

Have you ever wondered if galvanized steel can be welded to regular steel safely? Galvanized steel, known for its corrosion resistance, poses unique challenges when welding due to its zinc coating.

Why does steel rust, and how can we stop it? Galvanized steel offers a solution with its zinc coating. This article explores the galvanization process, its role in steel protection, and its historical evolution.

Why is galvanized steel sheet metal the backbone of modern construction and manufacturing? Its unique zinc coating offers remarkable protection against corrosion, making it indispensable in various industries.

Steel is everywhere, but not all steel is the same. Galvanized steel and stainless steel each offer unique benefits. Understanding their differences helps you choose wisely. In this post, you'll learn how these materials differ in corrosion resistance, strength, cost, and environmental impact.

Why does steel last decades in harsh conditions? The answer is galvanized steel. This metal, coated with zinc, resists corrosion. Galvanized steel is vital in modern industry, offering durability and cost-efficiency.

What Is Galvanized Steel? Everything To KnowHave you ever wondered why certain steel structures withstand the test of time while others rust away? Galvanized steel might be the answer. This durable material, coated with zinc, is crucial in industries like construction and automotive.

Why does galvanized steel matter so much in our world today? With its unique properties, it's vital across industries. Galvanized steel is steel coated with zinc for protection, offering rust resistance and durability.

Steel products coated with zinc have become a staple in industries worldwide, thanks to their excellent durability, corrosion resistance, and cost efficiency. Whether referred to as galvanized coil, GI coil, or galvanised steel coil (British spelling), these materials play a crucial role in construc

Application of galvanized steel coil in the production of steel pipes and boxesGalvanized steel coils are a backbone in making steel pipes and boxes—here’s why. Their zinc coating acts like a super-strong raincoat, stopping rust from eating through metal. For pipes, that’s a big deal.

IntroductionPrepainted galvanized steel coil is more than just a technical term—it’s a material that weaves into our daily lives in ways we often miss.

Introduction: What Makes Galvanized Steel the Go-To Choice?The Superpower of SteelGalvanized steel is everywhere because it’s simply unbeatable in terms of durability and cost-effectiveness.

A36 steel plate is one of the most widely used carbon steel materials in construction and manufacturing. Defined by the ASTM International A36 standard, this low-carbon steel combines affordability, weldability, and versatility. Its chemical composition includes iron, carbon (up to 0.29%), manganese

What is 4140 Alloy Steel?4140 alloy steel is a versatile and high-performance chromium-molybdenum steel renowned for its exceptional strength, durability, and adaptability across industries. As a medium-carbon steel alloy, it combines precise chemical composition with advanced heat treatment capabil

A36 steel plate is one of the most widely used carbon steel materials in construction and manufacturing. Defined by the ASTM International A36 standard, this low-carbon steel combines affordability, weldability, and versatility. Its chemical composition includes iron, carbon (up to 0.29%), manganese

For generations, engineers and builders have been in pursuit of materials that not only provide structural strength but also stand the test of time against the elements. In this quest, galvanized steel has emerged as a cornerstone in construction and manufacturing industries. From towering skyscrape

When it comes to carbon seamless tubes, choosing the right production process significantly impacts their performance, quality, and application. In this guide, we’ll explore the differences between hot-rolled seamless tubes and cold-rolled seamless pipes, highlighting their unique features, benefits

| Availability: | |

|---|---|

| Quantity: | |

Dx51d

ZHONG RUN

Product Description

| SPECIFICATION PARAMETER | |

Commodity | Dx51d Galvanized Steel Sheet |

Grade | Q195, Q235 |

SGCC, SGCH, SGC340, SGC400, SGC440, SGC490, SGC570 | |

SGHC, SGH340, SGH400, SGH440, SGH490, SGH540 | |

DX51D, DX52D, DX53D, DX54D | |

S220GD, S250GD, S280GD, S320GD, S350GD, S400GD, S500GD, S550GD | |

Standard: | AISI, ASTM, BS, DIN, GB, JIS |

Zinc coated: | 30 g/m2-275 g/m2 |

Spangle | Zero spangles (0.12-2.0 mm), 0.7-4 mm with small spangles, regular (big) spangles |

Surface treatment | Chromated, oiled and anti-fingerprint |

Thickness | 0.12-4.0mm |

Width | 600-2000mm |

Supply Ability | 40000MT/month |

MOQ | 5MT |

Packaging | Export standard, seaworthy |

Substrate | Cold rolled, Hot rolled |

ID | 508mm or 610mm |

Certificates | SGS, BV, ISO 9001 |

Trade Term | FOB, CFR, CIF |

Payment terms | T/T, L/C at sight, West Union, D/P, D/A, Paypal |

Delivery time | 14days after confirmed order |

Loading port | Tianjin port |

Container size | 20ft GP: 5898mm(Length)x2352mm(Width)x2393mm(High) |

40ft GP: 12032mm(Length)x2352mm(Width)x2393mm(High) | |

40ft HC: 12032mm(Length)x2352mm(Width)x2698mm(High) | |

Standard | GB/T 2518 | EN10346 | JIS G 3141 | ASTM A663 |

Grade | DX51D+Z | DX51D+Z | SGCC | CS Type C |

DX52D+Z | DX52D+Z | SGCD1 | CSTypeA.B | |

DX53D+Z | DX53D+Z | SGCD2 | FS Type A, B | |

DX54D+Z | DX54D+Z | SGCD3 | DDS Type C | |

S250GD+Z | S250GD+Z | SGC340 | SS255 | |

S280GD+Z | S280GD+Z | SGC400 | SS275 | |

S320GD+Z | S320GD+Z | - | - | |

S350GD+Z | S350GD+Z | SGC440 | SS340 Class4 | |

S550GD+Z | S550GD+Z | SGC590 | SS550 Class2 |

HOT-DIP GALVANIZED STEEL SHEET

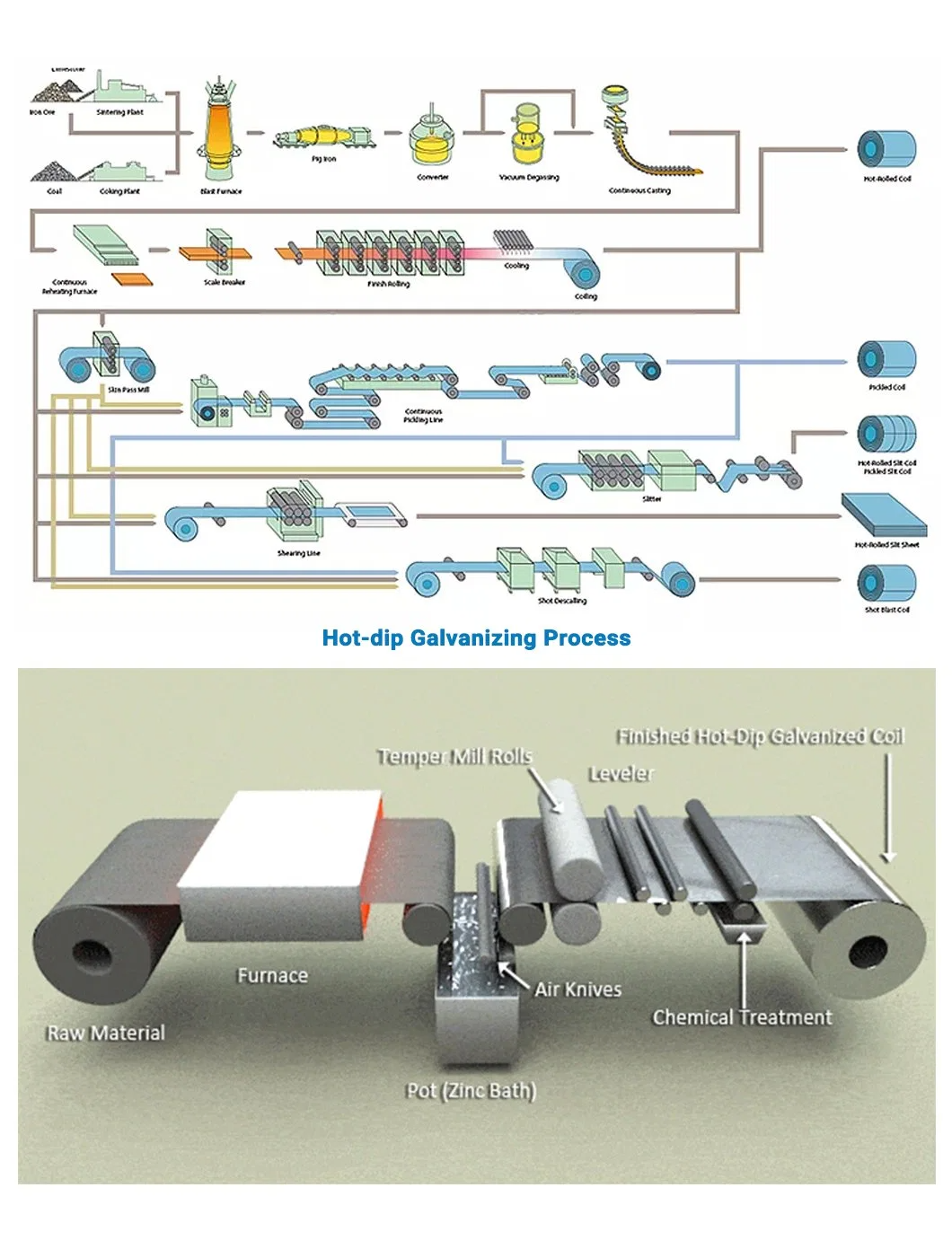

Hot-dip galvanized sheet is produced by immersing steel sheets in a molten zinc bath at approximately 500 °C, creating a robust zinc coating on the surface through a continuous galvanizing process. The zinc layer not only provides excellent corrosion protection but also enhances paint adhesion and weldability. As the most widely utilized and cost-effective method, it significantly extends the service life of steel sheets, making it ideal for various applications.

Difference Between Hot-Dip and Electro-galvanized Steel Sheets

The thickness of the zinc coating is crucial for corrosion resistance; a thicker zinc layer provides superior protection. Typically, hot-dip galvanized coatings range from over 30 g/m² to as much as 600 g/m², while electro-galvanized coatings are only 5 to 30 g/m² thick. Consequently, hot-dip galvanized steel sheets offer significantly better corrosion resistance. At Wanzhi Steel, we provide galvanized steel sheets with a maximum zinc layer thickness of 275 g/m² (Z275), ensuring optimal durability and longevity.

Main features of galvanized steel sheets

1.Strong anti-corrosion performance.

2.Good weather resistance.

3.Good welding performance.

4.Beautiful appearance.

5.Strong plasticity.

Product Show

Quality Inspection

Product Process

Method of Operation

Hot-dip galvanized steel sheets are processed by immersing them in a molten zinc bath at approximately 500 degrees Celsius. In contrast, electro-galvanized steel sheets undergo treatment at room temperature through electroplating or similar methods, which is why electro-galvanizing is often referred to as the cold galvanizing process.

Surface Smoothness & Adhesion

Electro-galvanized steel sheets typically exhibit a smoother surface compared to hot-dip galvanized sheets. However, their adhesion is not as strong. If you require galvanization on only one side, the electroplating method is suitable. On the other hand, hot-dip galvanizing ensures that both sides of the steel sheet receive a thorough zinc coating for enhanced protection.

Video

Application

Applications of galvanized steel sheets

Construction: Galvanized steel sheets are widely used in the construction field and are used to manufacture support materials for building structures, such as steel columns, steel beams and steel pipes. Galvanized steel sheets have excellent anti-corrosion properties and can effectively extend the service life of buildings.

Steel cable trunk lines: Galvanized steel sheets are often used in the manufacture of steel cable trunk lines to carry and protect power, communication and other cables. Its anti-corrosion performance and strength enable long-term use in outdoor environments, ensuring safe and stable transmission of cables.

Ventilation ducts: Galvanized steel sheets are widely used in the manufacture of ventilation ducts. Galvanized steel sheets have good corrosion resistance and plasticity, can meet the needs of ventilation ducts of different shapes and sizes, and ensure their long-term stable operation.

Agricultural greenhouse: As one of the main materials of agricultural greenhouses, galvanized steel sheets can provide good anti-corrosion protection and corrosion resistance. They are used to make greenhouse skeletons and covering materials to protect crops from the outside environment and improve crop yield and quality.

Billboards: Galvanized steel sheets are often used to manufacture outdoor billboards. It has good weather resistance and strong anti-corrosion properties, and can maintain stable appearance and quality under various climate conditions, improving the durability and aesthetics of billboards.

Rolling shutter doors: Galvanized steel plate is one of the commonly used materials for manufacturing rolling shutter doors. They have excellent strength and corrosion resistance, providing reliable safety protection and long-term use.

Galvanized Buckets: Galvanized steel sheets are commonly used to manufacture various types of galvanized buckets. Galvanized steel sheets provide excellent anti-corrosion protection during liquid storage and transportation, ensuring the quality and safety of liquids.

In short, galvanized steel sheets are widely used in many fields such as construction, steel cable trunks, ventilation ducts, agricultural greenhouses, billboards, rolling shutter doors, and galvanized barrels. Our company provides high-quality galvanized steel sheet products to meet the needs of different industries and is committed to providing customers with reliable anti-corrosion protection and excellent performance.