How to Choose the Right Carbon Steel Coil: Differences Between Hot-Rolled and Cold-Rolled Steel and Their ApplicationsWhen selecting the right carbon steel coil for your project, understanding the distinctions between hot-rolled and cold-rolled processes is crucial. The choice between these two type

IntroductionGalvanized pipe fittings and pipe have become indispensable in modern construction, manufacturing, and infrastructure projects. By applying a zinc layer to steel through the hot-dipped galvanize steel process, these pipes achieve superior corrosion resistance and durability. As a result,

Galvanized steel pipes are widely used across industries and construction projects because of their durability, corrosion resistance, and cost-effectiveness. When choosing materials for plumbing, structural frameworks, or industrial applications, selecting the best galvanized steel pipe ensures both

Choosing the Best Galvanized Pipe: Complete Buyer’s GuideWhen it comes to construction, water systems, or industrial frameworks, selecting the right pipe is essential. Among the most trusted materials, galvanized pipe stands out due to its strength, cost-effectiveness, and long service life. This gu

Have you ever wondered if galvanized steel can be welded to regular steel safely? Galvanized steel, known for its corrosion resistance, poses unique challenges when welding due to its zinc coating.

Why does steel rust, and how can we stop it? Galvanized steel offers a solution with its zinc coating. This article explores the galvanization process, its role in steel protection, and its historical evolution.

Why is galvanized steel sheet metal the backbone of modern construction and manufacturing? Its unique zinc coating offers remarkable protection against corrosion, making it indispensable in various industries.

Steel is everywhere, but not all steel is the same. Galvanized steel and stainless steel each offer unique benefits. Understanding their differences helps you choose wisely. In this post, you'll learn how these materials differ in corrosion resistance, strength, cost, and environmental impact.

Why does steel last decades in harsh conditions? The answer is galvanized steel. This metal, coated with zinc, resists corrosion. Galvanized steel is vital in modern industry, offering durability and cost-efficiency.

What Is Galvanized Steel? Everything To KnowHave you ever wondered why certain steel structures withstand the test of time while others rust away? Galvanized steel might be the answer. This durable material, coated with zinc, is crucial in industries like construction and automotive.

Why does galvanized steel matter so much in our world today? With its unique properties, it's vital across industries. Galvanized steel is steel coated with zinc for protection, offering rust resistance and durability.

Steel products coated with zinc have become a staple in industries worldwide, thanks to their excellent durability, corrosion resistance, and cost efficiency. Whether referred to as galvanized coil, GI coil, or galvanised steel coil (British spelling), these materials play a crucial role in construc

Application of galvanized steel coil in the production of steel pipes and boxesGalvanized steel coils are a backbone in making steel pipes and boxes—here’s why. Their zinc coating acts like a super-strong raincoat, stopping rust from eating through metal. For pipes, that’s a big deal.

IntroductionPrepainted galvanized steel coil is more than just a technical term—it’s a material that weaves into our daily lives in ways we often miss.

Introduction: What Makes Galvanized Steel the Go-To Choice?The Superpower of SteelGalvanized steel is everywhere because it’s simply unbeatable in terms of durability and cost-effectiveness.

A36 steel plate is one of the most widely used carbon steel materials in construction and manufacturing. Defined by the ASTM International A36 standard, this low-carbon steel combines affordability, weldability, and versatility. Its chemical composition includes iron, carbon (up to 0.29%), manganese

What is 4140 Alloy Steel?4140 alloy steel is a versatile and high-performance chromium-molybdenum steel renowned for its exceptional strength, durability, and adaptability across industries. As a medium-carbon steel alloy, it combines precise chemical composition with advanced heat treatment capabil

A36 steel plate is one of the most widely used carbon steel materials in construction and manufacturing. Defined by the ASTM International A36 standard, this low-carbon steel combines affordability, weldability, and versatility. Its chemical composition includes iron, carbon (up to 0.29%), manganese

For generations, engineers and builders have been in pursuit of materials that not only provide structural strength but also stand the test of time against the elements. In this quest, galvanized steel has emerged as a cornerstone in construction and manufacturing industries. From towering skyscrape

When it comes to carbon seamless tubes, choosing the right production process significantly impacts their performance, quality, and application. In this guide, we’ll explore the differences between hot-rolled seamless tubes and cold-rolled seamless pipes, highlighting their unique features, benefits

| Availability: | |

|---|---|

| Quantity: | |

SGCC

ZHONG RUN

Product Description

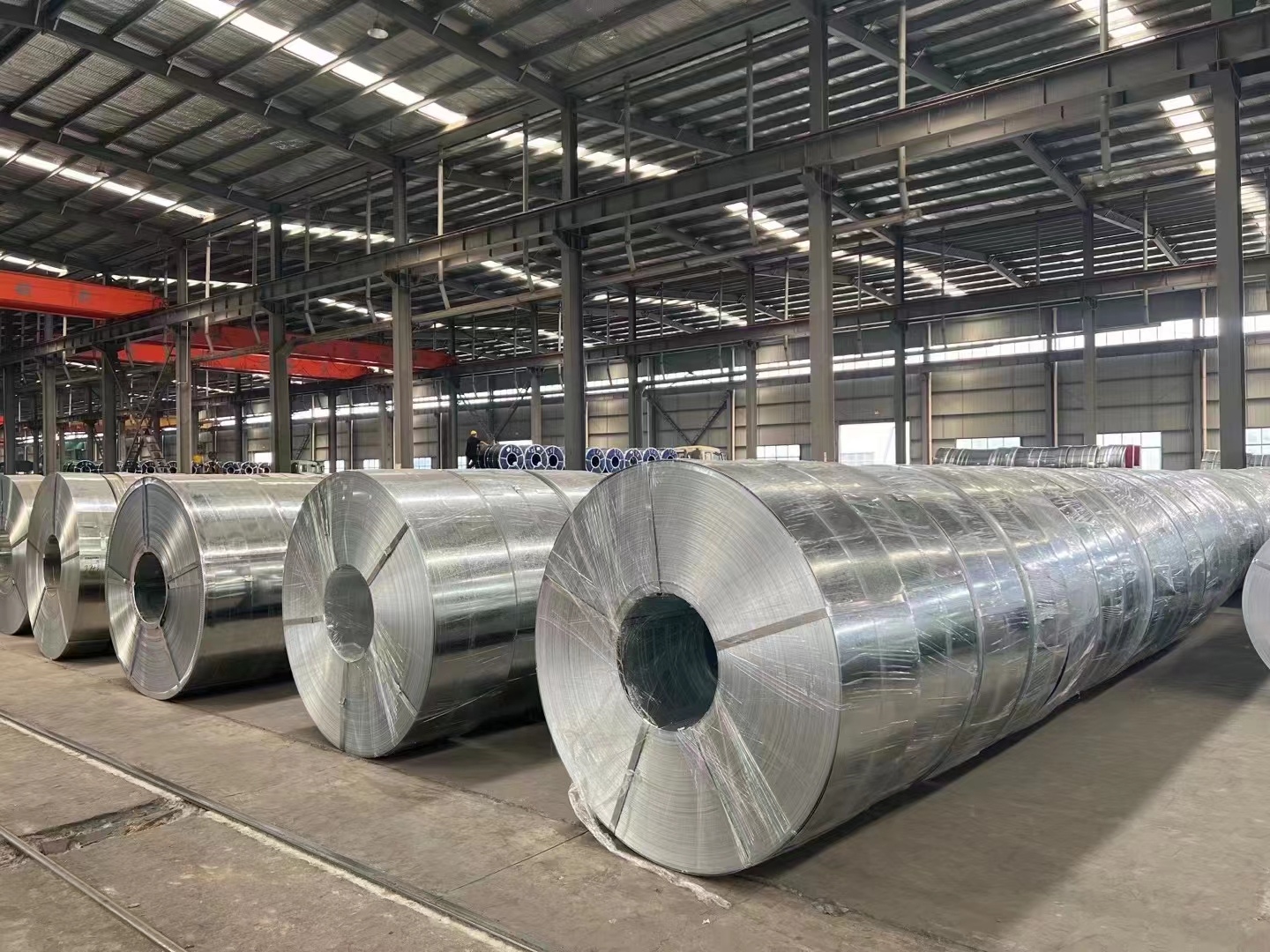

Galvanized Iron Coil, commonly referred to as GI Coil, is produced by immersing cold-rolled steel in a molten zinc bath through the continuous hot-dip galvanizing process. The zinc coating protects the base steel from rust and extends service life in both indoor and outdoor environments.

With excellent formability, weldability, and paint adhesion, GI coils are suitable for cold forming, stamping, bending, and roll forming into various finished products. They are available in different spangle sizes, coating weights, and surface treatments to meet industry-specific needs.

Base Material: Cold rolled steel (SPCC, DC01, Q195/Q235)

Standard: ASTM A653 / JIS G3302 / EN 10346

Zinc Coating: Z40 – Z275 g/m² (optional Z350 / G90)

Thickness: 0.12mm – 3.0mm

Width: 600mm – 1500mm

Coil ID: 508mm / 610mm

Coil Weight: 3 – 10 metric tons

Surface Finish: Regular spangle / Zero spangle / Minimized spangle

Surface Treatment: Chromated / Oiled / Dry / Skin-passed

Strong corrosion resistance in humid and marine environments

Excellent formability for bending, punching, and profiling

Weldable and paintable for various fabrication processes

Cost-effective protection compared to stainless steel

Recyclable and RoHS compliant

Product Show

Product Advantage

Galvanized steel coils offer exceptional corrosion resistance, ensuring the steel’s integrity is preserved for extended periods, even in harsh environments. The protective zinc layer acts as a barrier, effectively shielding the steel from exposure to air, moisture, and chemicals, significantly prolonging its service life.

Galvanized steel coils possess excellent mechanical properties, including high strength, good plasticity, and strong weldability. These characteristics make them ideal for use in construction, manufacturing, and the automotive industry.

Our galvanized steel coils are available in a wide range of specifications and thicknesses to suit diverse customer needs. We offer customized processing services, including cutting, coiling, and stamping, to meet the specific requirements of various applications.

Product Video

APPLICATION

Galvanized iron coils are widely used in construction, automotive, and industrial manufacturing sectors:

Roofing sheets & wall panels – corrugated, trapezoidal, tile types

HVAC ducts and ventilation pipes

Automotive body parts & reinforcement panels

Electrical enclosures & appliance housing

Light steel frames & structural supports

Furniture, shelving, metal cabinets, fencing panels

Formwork, packaging drums, and signboards